HVAC and Smart Building Technology for Living Comfort

Heating, ventilation and air conditioning (HVAC) technology is becoming more and more important for residential and commercial buildings as living comfort is directly linked to indoor temperature, humidity and air quality. Building automation and smart building technology further increases reliance on accurate sensing. The total energy consumption, CO2 footprint and operation costs of single homes, commercial and industrial buildings directly depend on the quality of the HVAC installation and its integration in the sensor network.

Temperature Sensors Are Crucial in HVAC Applications

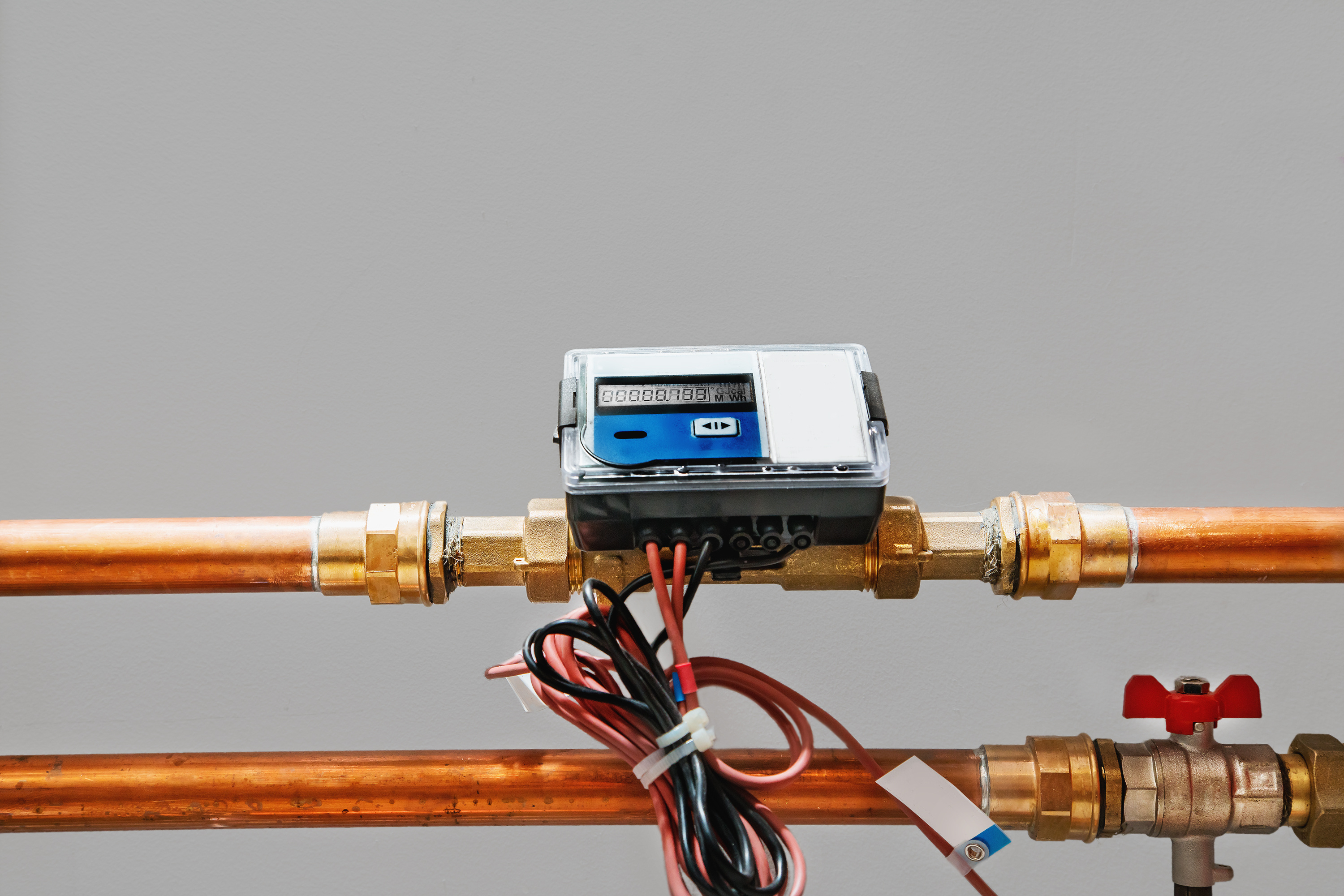

Temperature sensors play an important role for HVAC applications; not only to control indoor room temperatures, but also to measure and control the temperature in installed pipes and ducts that supply buildings with heated water or cold air. Sensors also help to precisely measure household energy consumption via heat or cold meters.

Many HVAC applications are in the ambient to low temperature range. Devices using temperature sensors include thermometers, thermostats, smart valves, indoor controls and control units. Furthermore, there are many different equipment types, such as heating furnaces, heat pumps, chillers, cooling towers, air conditioner systems, etc. that are controlled and managed by temperature sensors.

Sensor Technologies in HVAC

Different sensor technologies are used in the HVAC environment. Resistance Temperature Detectors (RTDs) and NTCs (Negative Temperature Coefficient) thermistors are most commonly used.

Platinum-RTDs and the Influence of Sensor Design

Platinum temperature sensors (Pt-RTDs) have superior drift behavior, higher long-term stability, better repeatability, and higher temperature capability. Typical RTDs used in HVAC have resistance values of 500 Ohm (Pt500) and 1000 Ohm (PT1000). Contact us for an in-depth comparison of Pt RTDs and NTC sensors.

The sensor element and specific sensor probe design influence the temperature measurement properties. For many HVAC applications, stainless-steel probe housings are used to protect the Pt element. Fabricating a precision duct or immersion type sensor starts with a wired RTD sensor chip e.g. YAGEO Nexensos M-Type .

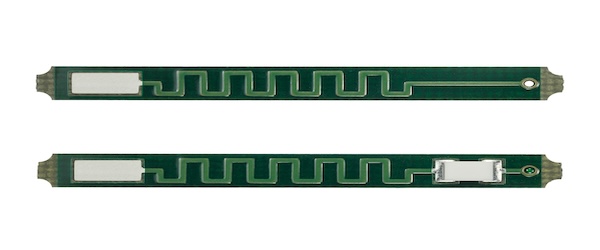

Pt-RTDs Pre-Mounted on PCBs and SMD Type RTDs

YAGEO Nexensos supplies Pt-RTD elements pre-mounted on small PCBs. Designed for high-precision temperature measurement, the PCB element is optimized for easy assembly into sensor probes and supports efficient production processes. Its features make it a superior solution for heat meters and other HVAC applications.

The RTDs in standard SMD packages are typically used on board-based temperature sensors, in wall thermostats or for temperature compensation of other sensors (e.g. gas sensors).

YAGEO Nexensos offers both product types in its standard portfolio.

Individual Advantages for Your Application

Advantages of Platinum-RTDs: High Accuracy, Standardized Linear Signal, Long-Term Stability, Low Drift – Help To Save Costs along the Value Chain

Pt-RTDs provide high accuracy, low long-term drift and a standardized linear signal. The high measurement repeatability and tight temperature control help reduce the overall error budget in complex and interconnected sensor networks. The excellent long-term stability and interchangebility of Pt-RTDs reduce re-calibration and repair expenses.

The linear signal characteristic simplifies the electronic design process and permits less complex sensor electronics. In addition, it supports standardization and allows easy sensor replacement even after many years of use.

Pt-RTDs – Accurate and Reliable Temperature Measurements in HVAC Equipment and Smart Home Controls

Pt RTDs are used in furnaces, gas burners and heat pumps, providing accurate measurement and control. Steam and super-heated steam systems depend on the large operating temperature range of Pt-RTDs to provide reliable temperature monitoring. Wood burning pellet stoves operate at high temperatures in order to reduce exhaust gas and CO2 emissions. Pt-RTDs ensure safe operation at temperatures up to 800 °C and beyond, resulting in optimized combustion efficiency. The high temperature capability of Pt-RTDs supports the most demanding applications, under the harshest conditions.

Pt-RTDs also provide accurate and reliable temperature measurement for low-temperature HVAC applications, such as chillers and industrial cooling towers.

Precision temperature monitoring and control is essential for smart homes and buildings. The sensors and controls can be stand-alone devices for indoor air and temperature monitoring or part of equipment installations that provide integration and automation functions. The recent trend towards smart buildings drives the need for more and more sensors and integration of equipment within sensor networks. Pt-RTDs help make these networks more reliable, highly accurate and easy to maintain.

Platinum-PCB Sensors in Heat Metering with Highest Demands in Accuracy

Heat and cold meters have strictly regulated accuracy and service life requirements. Platinum elements provide the high accuracy and long-term stability required to meet the standards of this application. Heat meters use sensor probes that are installed in the inflow and outflow of the water pipes of an apartment/flat. The flow and temperature difference are used to precisely calculate the energy consumed to heat a building unit. SMD Platinum sensors mounted on a PCB are typically used in this application. The PCB design simplifies the probe assembly process and provides thermal decoupling of the SMD sensor from the solder pads and the connection wire. The latter further increases the accuracy of the system. More details about PCB in heat metering can be found here .

Pt-RTDs – High Performance, Long Sensor Lifetime, and Reduced Maintenance Rates Provide Superior Life-Cycle Costs

Performance and cost of a temperature measurement element should always be carefully regarded in the context of the overall system and measurement requirements. A Pt element achieves the highest performance when appropriately packaged for the application environment and paired with compatible signal processing electronics.

Ultimately, cost for the entire HVAC solution and its TCO are key decision criteria for a potential buyer.

Unfortunately, sensor lifetime and redundancy, ease and cost for sensor replacement, and the overall accuracy of sensor networks, which can be positively influenced by Pt sensors, need to be considered. Pt-RTDs increase reliability of sensors and allow easy replacement without re-calibration. This supports reduced maintenance rates and downtime in production processes, and increase reliability of expensive equipment or building automation systems.

Likewise Pt-RTDs support accurate and precise sensor networks and consequently tight control of energy generation, distribution and usage. Eventually this can add to the overall saving for end-users or building operators.