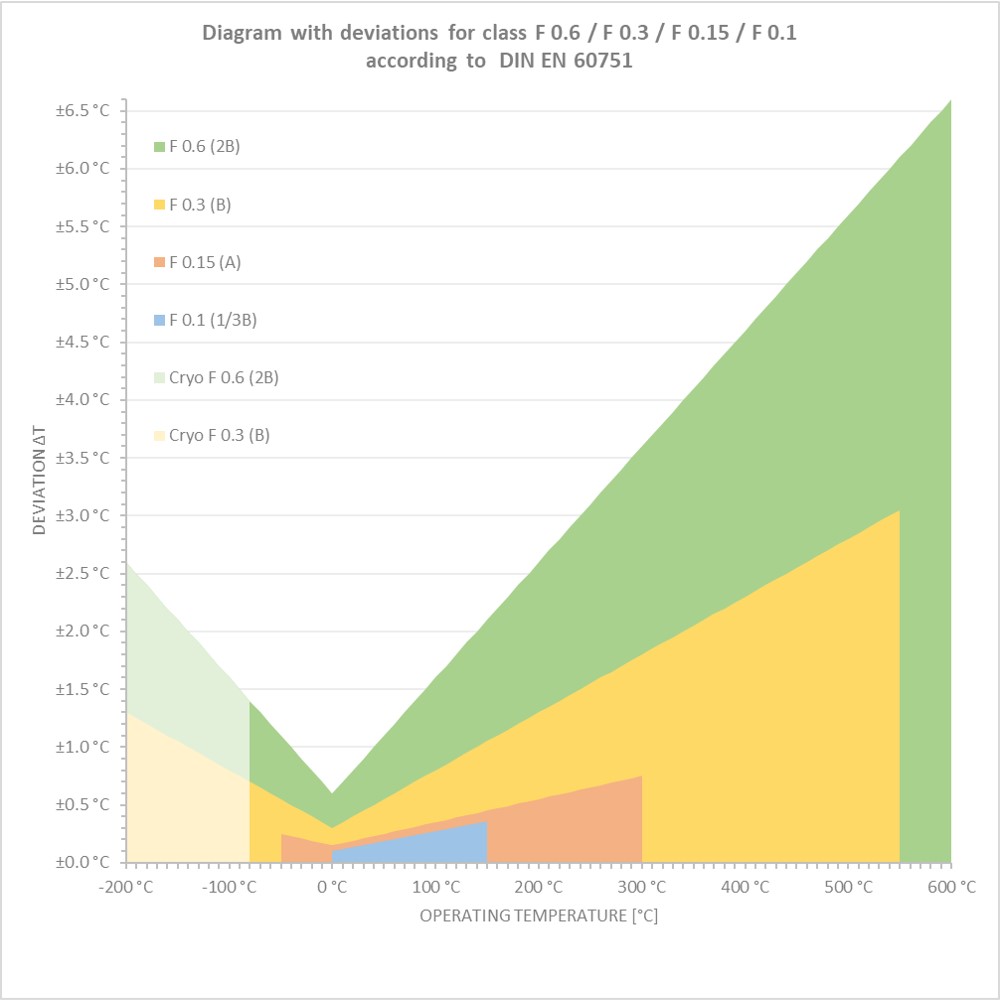

| Tolerance Class | Temperature Range* | Deviation |

| F 0.6 (2B) | -70 °C - 500 °C | ± 0.6 Kelvin at 0 °C |

| F 0.3 (B) | -70 °C - 500 °C | ± 0.3 Kelvin at 0 °C |

| F 0.15 (A) | -50 °C - 300 °C | ± 0.15 Kelvin at 0 °C |

| F 0.1 (1/3B) | 0 °C - 150 °C | ± 0.1 Kelvin at 0 °C |

Further tolerances on request.

Tolerance Graphs*

*The temperature ranges may deviate for specific sensor elements. The information on the data sheet takes precedence.

Reference Tables

The reference tables conform to the International Industrial Standard IEC 60751 for pt100, pt200, pt500, pt1000 and pt2000.

Reference tables for other temperature coefficients: Pt200 TC 3770

Basic and Limit Values of Platinum Temperature Sensors

Platinum temperature sensors function on the basis of the change in electrical resistance of Pt vs. temperature. The relationship can be described by the following characteristic polynomial:

For a temperature range between –200 °C to 0 °C:

Rt = R0 [1 + At + Bt2 + C (t-100 °C) t3]

For a temperature range between 0 °C to 850 °C:

Rt = R0 (1 + At + Bt2)

B is so small such for most applications it can be assumed that Rt and temperature are linearly dependent.

The polynomial constants are specified in the international standards for platinum temperature sensors (IEC 60751 / DIN EN IEC 60751), as follows:

A = 3.9083 x 10-3 °C-1

B = -5.775 x 10-7 °C-2

C = -4.183 x 10-12 °C-4

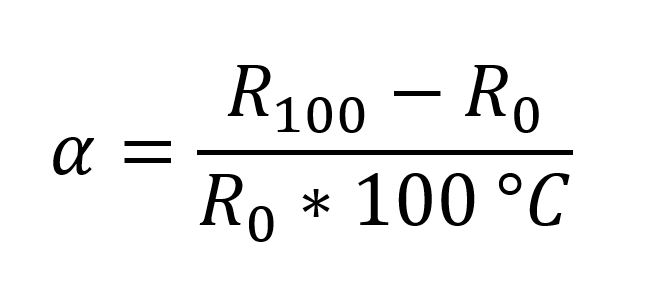

The temperature coefficient (TCR or α) of platinum temperature sensors is positive, and defined as:

Where R100 is the resistance at 100 °C and R0 the resistance at 0 °C.

This value is the slope of the linear approximation of the characteristic polynomial between 0 °C and 100 °C. The standard DIN EN IEC 60751 for platinum temperature sensors specifies a TCR of 0.00385055 °C-1. In addition to this standardized temperature coefficient, other customer-specific sensors with temperature coefficients of 0.003750/°C and other values are available upon request.

Depending on the materials and processes used to manufacture the platinum temperature sensors, slight deviations from the ideal constants and the optimal characteristic curve can occur. These deviations determine the working temperature range and the accuracy classes for each type of platinum temperature sensor. Within these limits, platinum temperature sensors are completely interchangeable.

Frequently Asked Questions

Platinum (Pt) resistance elements can be supplied as standard in class F 0.3 (B), F 0.15 (A) and F 0.1 (1/3B). The tolerance 1/10 class B is available on request.

I’ve Seen References to a F 0.3 Tolerance. What Does This Mean?

“F 0.3” tolerance is equivalent to a class B tolerance (0.3 indicates ± 0.3 °C @ 0 °C). The tolerance nomenclature for platinum temperature sensing elements was revised in the IEC 60751 2008-07 specification (also in the DIN EN IEC 60751 2009-05 specification). The following table relates the old tolerance designation to the new.

| Old Tolerance Designation | New Tolerance Designation |

| Class ⅓B | F 0.1 |

| Class A | F 0.15 |

| Class B | F 0.3 |

| Class 2B | F 0.6 |

Is It Possible to Work at 400 °C in Tolerance Class F 0.15 (A)?

The tolerance class F 0.15 (A) is specified in DIN EN IEC 60751 for a temperature range from -50 °C up to 300 °C. A temperature of 400 °C is outside the defined range for F 0.15 (A). E.g. Tolerance class F 0.3 (B) would be suitable for this temperature range.

Exposure to temperatures above the specified maximum can lead to ageing effects. Stressing the sensor above the maximum temperature range could also lead to performance losses and further deviation at lower temperatures.