Sensing in Health Covers a Wide Variety of Different Applications

Temperature sensing in healthcare is critical in both in-vivo and in-vitro sensing. Not only are many medical procedures temperature-sensitive, many diagnostic and lab instruments also require accurate reference temperature measurement to ensure accuracy. Temperature sensing in health applications covers a wide range, from cryogenic applications such as drug development and vaccine transport to high-temperature applications such as gas chromatography, and harsh environments found in autoclaves and sterilizers.

pH measurement determines the alkalinity or acidity of a solution. pH measurement is highly temperature dependent. In fact, pH of a fluid is defined at 25 °C and pH measured at any other temperature requires an appropriate temperature compensation. A pH measurement is only as accurate as the reference temperature detection.

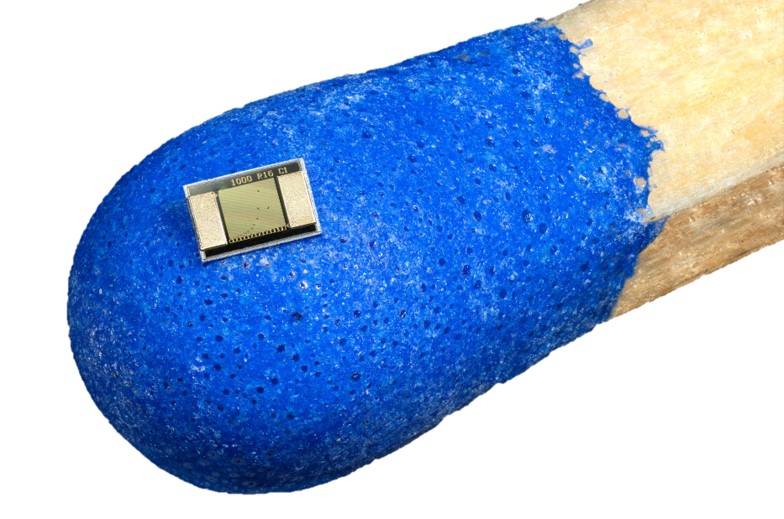

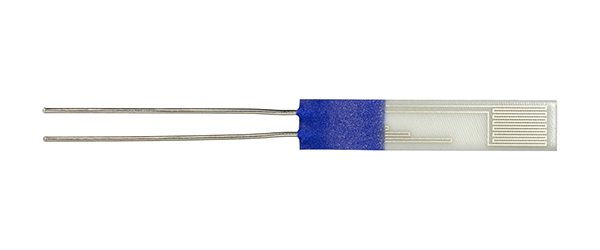

Pt RTDs measure temperature accurately, providing accurate temperature compensation, resulting in a precise pH measurement. Advanced pH meters have extremely miniaturized, built-in Pt RTDs. In addition to providing accurate temperature readings, they also contribute to a sleek integrated design that eliminates the need for a separate temperature probe. These pH meters also have an advanced microcontroller that provides automatic temperature compensation (ATC), resulting in quick error-free readings in real time.

Pt RTDs are characterized by constant availability of a standardized product, linear characteristics and a small form factor for mounting in the tips of narrow pH electrodes.

Autoclaves and Sterilizers are used in the medical industry to safely reuse surgical instruments, implanted medical devices and surgical drapes and linens. With the rise in many infectious diseases caused by multi-resistant pathogens, adequate and proper sterilization and disinfection is needed not only in hospitals and clinics but also in small practices such as dentistry, etc.

Autoclave and sterilizers operate anywhere between 100 to 134 °C and work in multiple cycles to satisfy the high demands of busy medical practices.

Pt RTDs temperature sensors provide high accuracy and low measurement drift, contributing to strict adherence to sterilization and autoclaving standards over the entire operational lifetime. Inaccurate temperature measurement carries the risk of spreading infection. On the other hand, overheating may impact the lifetime of medical products. The robust Pt RTD design enables the end products to withstand the harsh cycle times of the sterilization process.

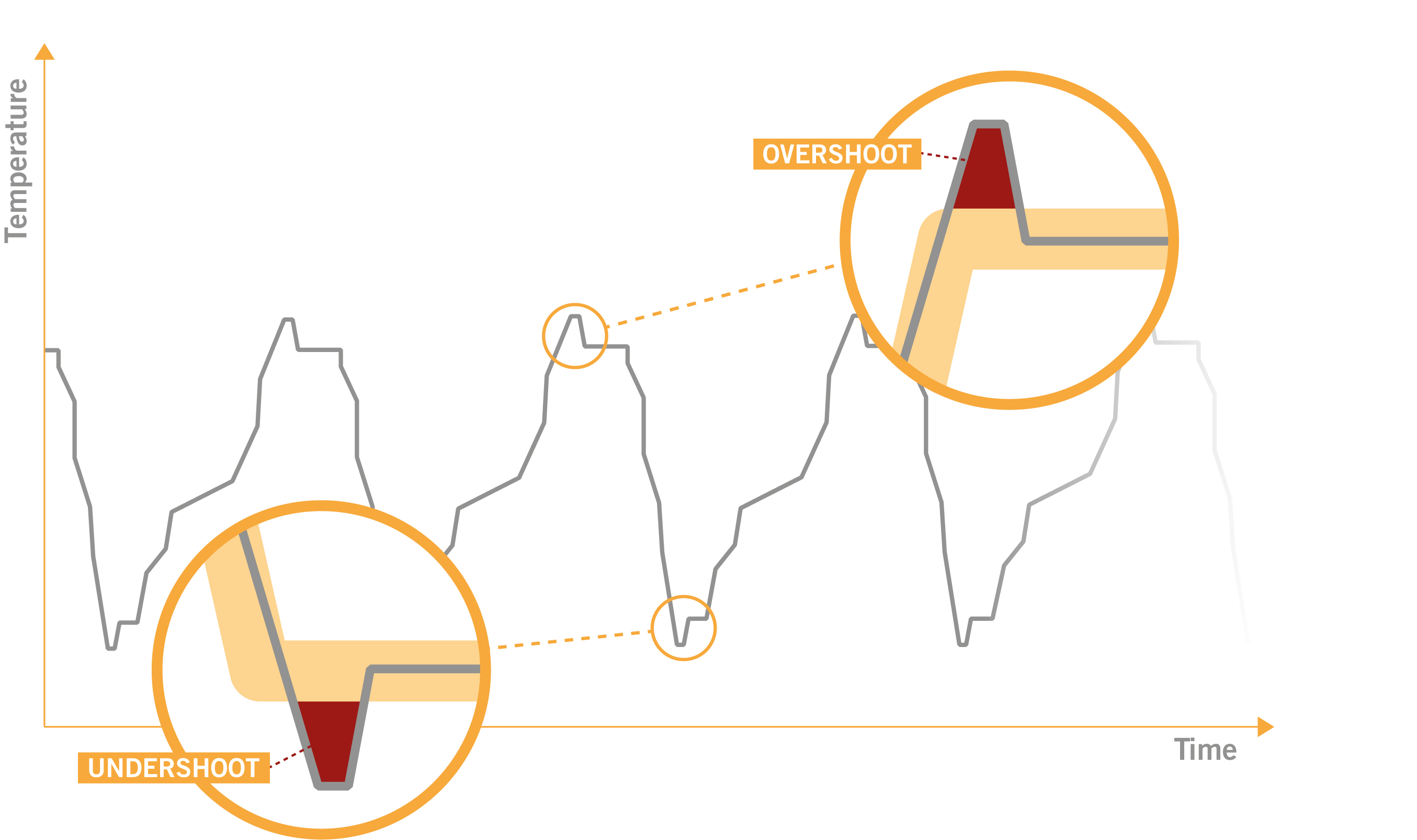

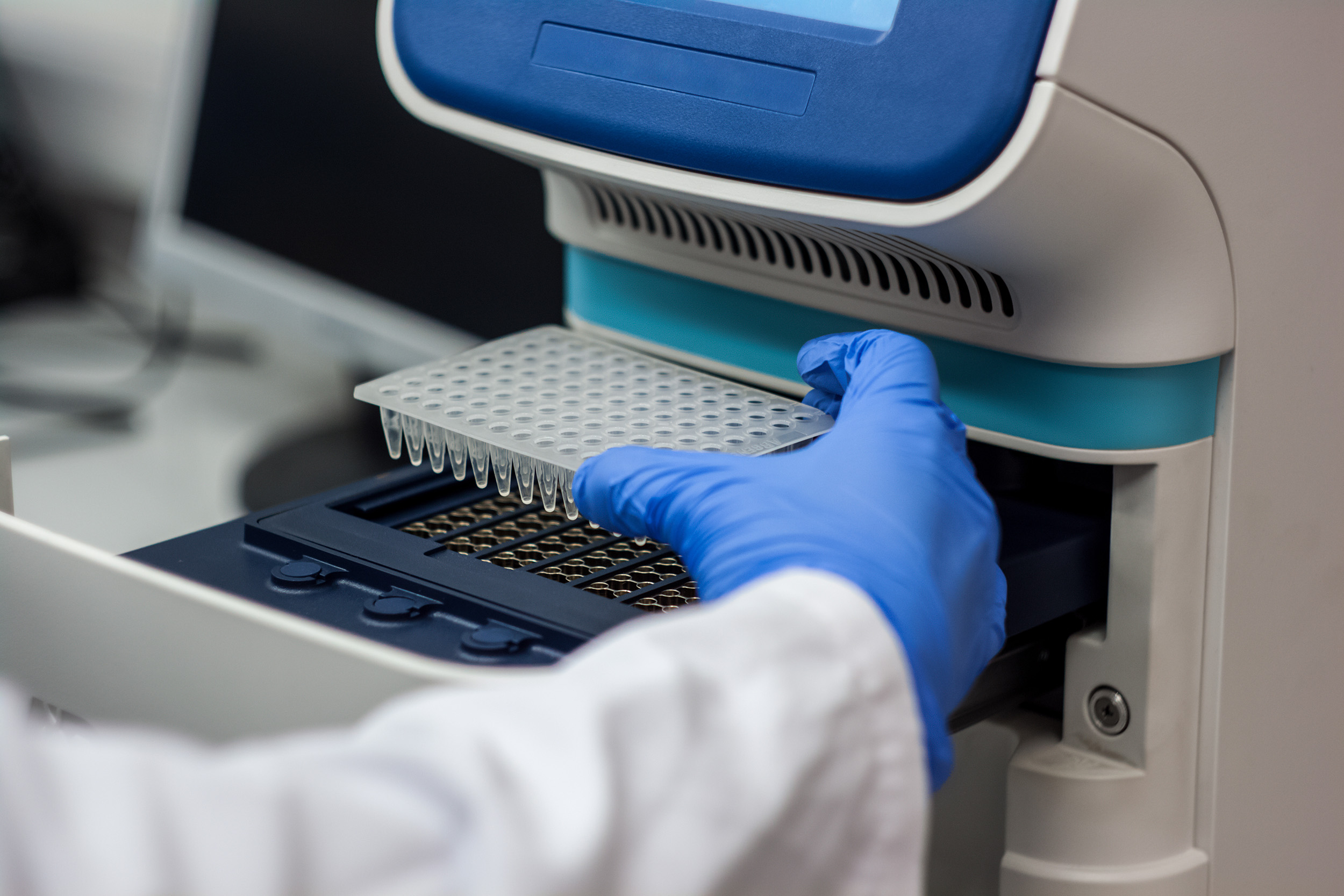

Be it biotech research or simply identifying covid positive individuals, the PCR machine is the equipment of choice for scientists and lab technicians. Platinum RTD temperature sensors not only improve the accuracy of genetic material amplification by supporting accurate temperature in different phases of the thermal cycling block, but also avoid temperature over and undershooting as they have fast response times.

Thermal cycler temperature accuracy may be a critical factor in the success or failure of a PCR reaction. Temperature accuracy is particularly important during annealing temperature optimization, which requires both accuracy and consistency in the thermal cycler block.

Overshooting and undershooting is controlled by machine manufacturers with better and advanced algorithms. These algorithms get their input from temperature sensors. Any lag in the response time of sensor could decrease the efficacy of these algorithms and other temperature control mechanisms. Nexensos Platinum RTD sensors have the capability to improve response time and thus avoid over and undershooting. Moreover, the form factor and miniaturization of these sensors can help build designs that improve response times further.

Over the period of time, many temperature sensors start giving some drift that results in inaccuracy of temperature data. Thus, there is a constant need in calibrating these sensors to improve the efficiency of PCR machines. Nexensos Platinum based RTD sensors can provide repeatable and reliable output with no or rather minimum drift that avoids calibration efforts in these thermal cyclers.

Providing a perfect cold chain for temperature-sensitive pharmaceutical products, such as vaccines and other biologicals, is a major logistical challenge for the pharmaceutical industry.

Pt RTDs are a perfect fit for harsh cryogenic sensing applications. Pt RTD sensors provide reliable and accurate temperature measurement in dry ice (-78 °C), with a capability going down to -200 °C. Pt RTDs also exhibit extremely low drift, even after years of service, ensuring reliable data collection for the operational life of the measurement device. This reliability translates to precise monitoring of temperature-sensitive biochemical synthesis processes, secure temperature control and monitoring for the complete cold chain logistic, from shipment to storage.

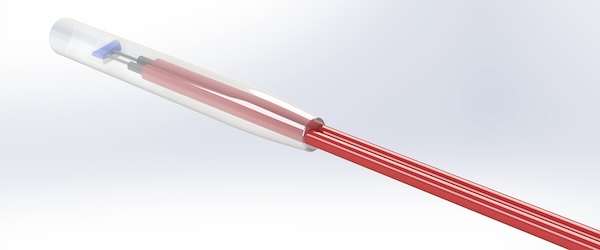

Medical technology, diagnostics and wearables are examples of applications that require high-sensitivity temperature measurement. Miniaturization is a key design challenge in many innovative health care applications. Tiny temperature sensors allow temperature sensing close to critical locations such as surgical wounds, or in directly embedded wound catheters used to monitor the healing processes.

Quite often, temperature sensors are combined with other sensors to allow for multi-parameter sensing. This configuration provides precise temperature detection and a reliable reference temperature for sensors detecting electrochemical parameters, such as pH value or concentration of different ions and other parameters.