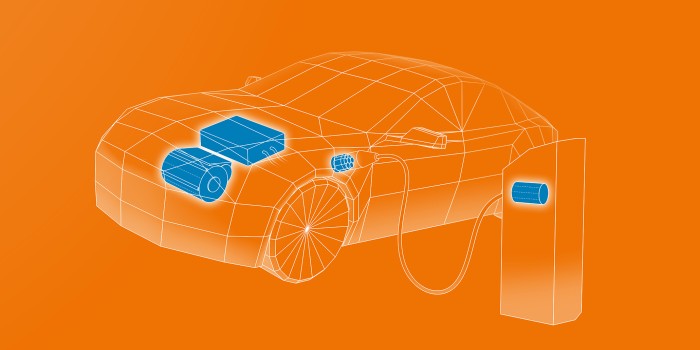

Temperature Sensors Increase Reliability and Safety

Reliable and precise temperature sensing is mandatory for plenty of positions in an electrified vehicle: YAGEO Nexensos facilitates safe and high-performing components for electric vehicles with platinum-based temperature sensor elements and sensor assemblies. Our current and steadily expanding portfolio supports applications in e-motors and charging infrastructure and opens design freedom for new layouts and materials in power electronics. With our established solutions, which are already used by numerous customers worldwide, we contribute to higher performance, efficiency and sustainability of electric vehicles.

Application Areas and Advantages of Platinum Temperature Sensor in Electric Vehicles

Essential competitive advantages can be gained through the specific performance benefits of platinum temperature sensors, such as reliable long-term stability, sensor element layout but also mounting options of sensor assemblies. These benefits provide the conditions for product optimization and create room for innovative technology advancements. These are, for instance, allowing for new materials and operation conditions in power electronics or alternative handling processes and installation options. Additional benefits can be gained when innovative designs or handling and packaging options ease the entire production process.

Exact customization to the respective requirements of the application is a leverage to achieve the best possible functionality, precision and reliability. Therefore, our experts work closely with your application development teams on design options and innovative solutions. YAGEO Nexensos offers standardized as well as customized platinum temperature sensor solutions for applications in electromobility - with the highest quality standards "Designed in Germany" while complying with EN ISO 9001 as well as IATF 16949. Whether for monitoring the electrical drive trains or the temperature control in charging equipment and in power electronics: our innovation power is as powerful as the new application field e-mobility.

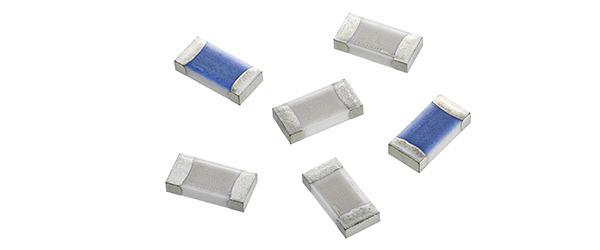

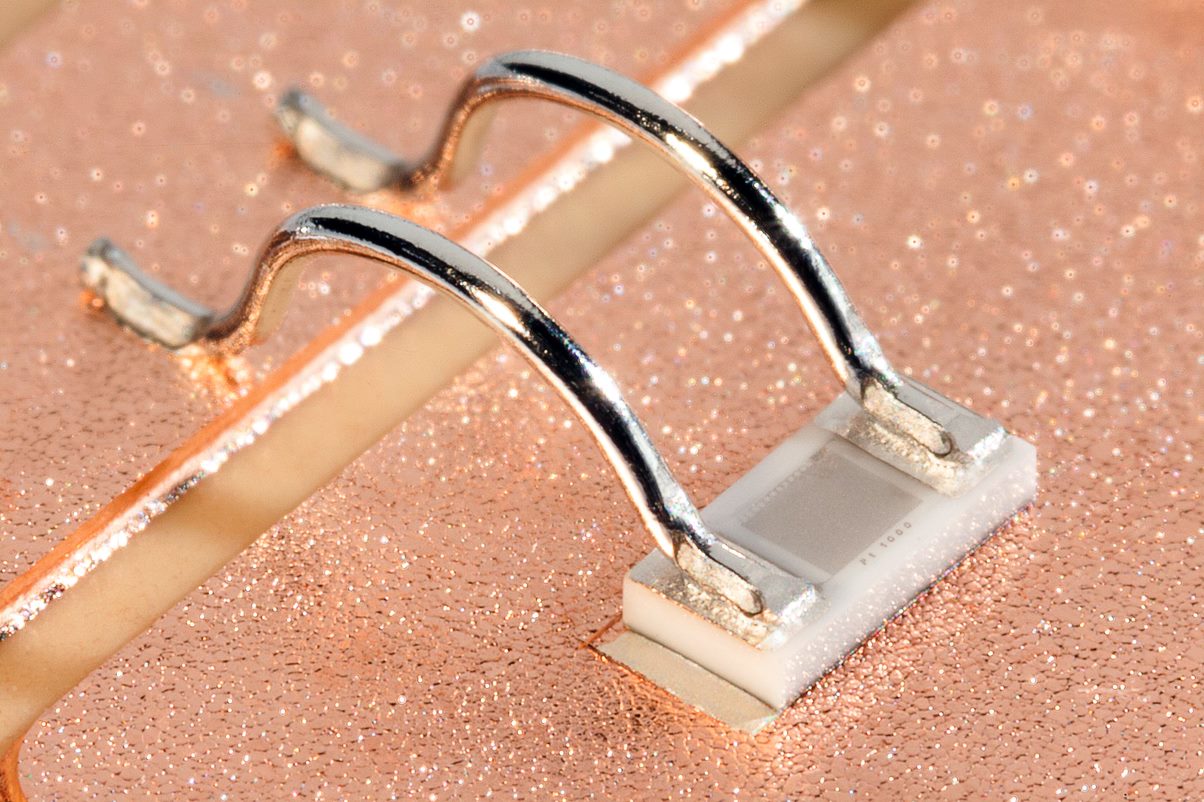

Power electronics is the pacemaker of electric vehicles. New materials such as SiC or GaN are engaged to increase efficiency and contribute to longer driving ranges. The operation at elevated temperature of up to 200 °C makes new connection technologies mandatory. The layout of our SMD-type temperature sensors is designed to allow for standard Ag-sinter processing due to a state-of-the-art backside metallization. The electrical insulation of the sensing layer from the substrate opens new possibilities to position the sensor in unprecedented proximity to the heat source, the power die which not only increases speed and accuracy but also contributes to more compact designs.

Advantages of Sinterable and Solderable SMDs in Power Electronic Applications

- Chip assembly on the substrate by standard silver sinter processing

- Optimal thermic coupling (quick response time) through silver sintered connections

- Wide operation window: Application temperature range from -50°C to over +200 °C, depending on connection technology

- Electrical insulation between board and bond pad allows for potential free positioning direct at the heat source or die, enabling reduced complexity of the substrate

- Optimized signal stability at high precision with standardized Pt-characteristics for long-term reliability

- Fast and reliable connection with state-of-the-art bonding solutions (e.g., YAGEO Nexensos Al-thick wires)

- RoHS compliant

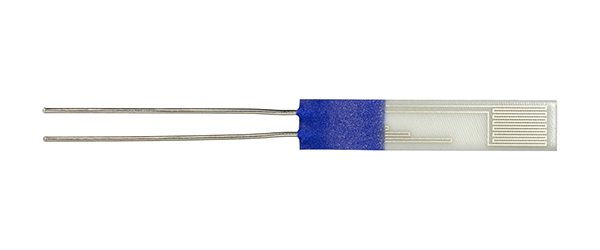

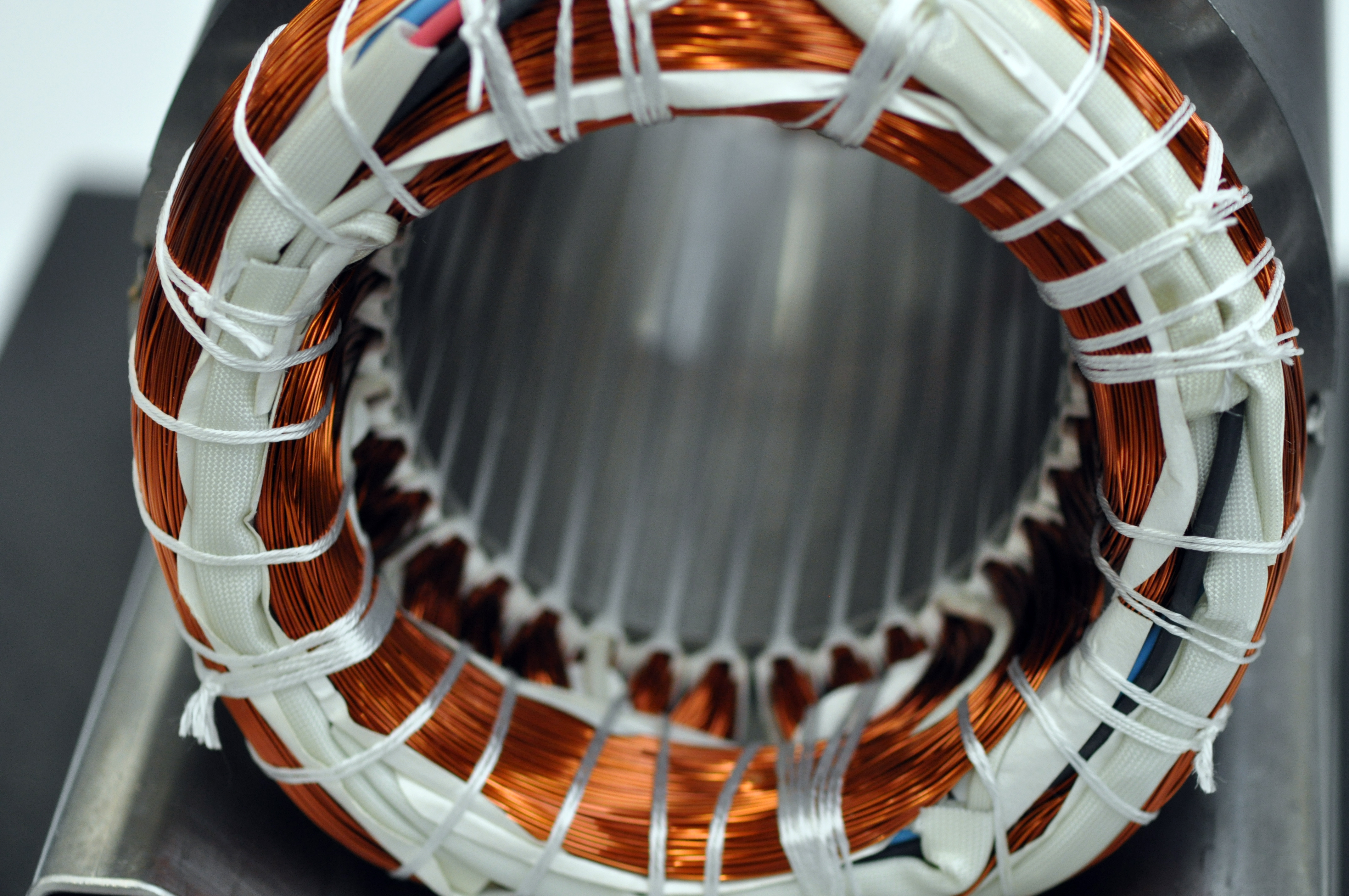

The e-motor turns electric power to dynamic and motion: protection and safe conditions are key for long-lasting operation. Whether replaceable or mounted to survive the entire operational lifetime, the temperature sensor has to be reliable, drift-free even after repeated temperature spikes and easy to be integrated in the production process. We at YAGEO Nexensos provide sensor assemblies based on platinum-based sensor elements – guarantee for long lifetimes; in combination with new and customizable mounting options a multitude of possibilities help our customers for optimal designs.

Advantages of Temperature Measuring with RTDs in Electric Motors

- Drift stability over long operational lifetimes

- Robust encapsulation and extension wires, high dielectric strength for safe and sustainable operation

- Durability by material selection for e-motor environments: IP67 and IP68 certification, proven oil resistance

- Precise and stable measurement accuracy over a wide temperature range

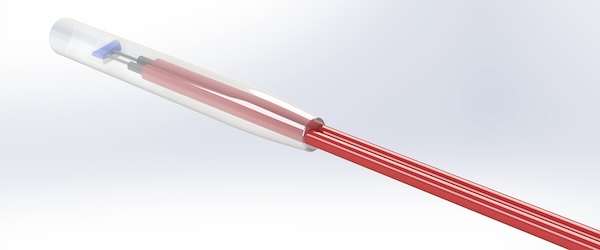

Charging with maximum power requires one key parameter: safety. Optimizing charging times means increased charging power which goes hand in hand with even more precise determination of potential hot spots. Platinum sensors’ characteristics in drift stability, response behavior and precision make it possible to meet stringent safety requirements for people and materials; optimized designs allow for positions at locations in the tip of the charging connectors – rendering potential hot spots visible, shortening response times to the minimum, and provide signal stability over the entire operational lifetime. And when it comes to the new GB20234.4 standard in China: our temperature sensor elements provide security for any new regulation targeting for maximum safety in operation.

Performance Advantages for Charging Equipment by Platinum Sensor Elements and Sensor Assemblies

- Increased safety and high charging performance by stable signal even after repeated temperature cycles

- Fast response to ensure safety for operators and material

- Miniaturization of sensor solutions to get close to potential hotspots and to further shorten response times

- Wide portfolio to suit your need: SMD-type sensors for applications on connecting components; sensor assemblies for in-pin detection

- Certainty for new regulations, compliance with existing quality requirements and regulations