1000 °C - New Pt Thin Film Sensors for Exhaust Gas Treatment Systems in Gasoline-Fueled Vehicles

Modern gasoline engines have significantly higher energy density and considerably lower emissions. They are designed to work with many rapid thermal cycles at higher temperatures up to 1000 °C to achieve the desired efficiency. CO2 fleet emissions limits required by law and the emissions rules of the EURO and other international standards, will become even more important.

Meeting these major challenges will require sophisticated technology. Controlling the processes plays a significant role here, as does precise data measurement. Precision is required even under difficult conditions, such as high temperature variations, harsh environments, and severe mechanical stress.

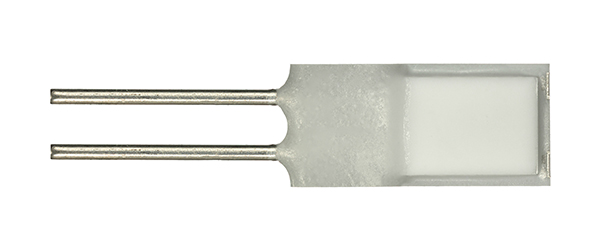

To meet the high requirements of this application and to allow the use of efficient and existing signal interfaces and electronics, YAGEO Nexensos has launched the HDZ sensor. This PT200 RTD It is designed for operation temperatures up to 1000 °C and can withstand 1100 °C short-term.

With this development YAGEO Nexensos expands the application of the PT200 product family to all exhaust-related applications, including turbo charger and Otto T3.

Platinum Sensors Ensure Low Emissions in Modern Diesel Cars

Precise Temperature Measurement Even in Extreme Temperatures and Challenging Applications

Since the 90s YAGEO Nexensos produces millions of platinum sensors for diesel exhaust gas system every year, to ensure compliance with emissions limits.

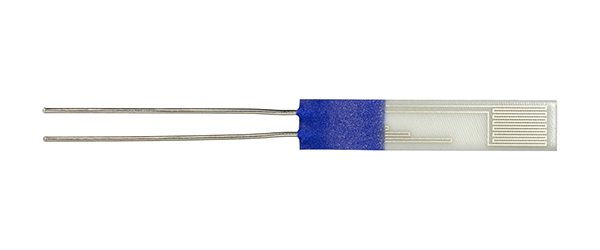

In diesel exhaust gas systems, sensors operate at temperatures up to 900°C for several years. Its robustness under harsh conditions and the low signal drift make PT200 RTDs the preferred solution to monitor particle filters and oxygen catalyst. Pt-RTDs of our HDA series generated a linear and highly accurate measuring signal in the full operation range from -50 °C up to 900 °C. This allows an initial functionality check of the sensing system directly when starting the cold engine.

Outstanding chemical and mechanical stability and resistance to moisture, climate, and other environmental factors make measurements reproducible over many tens of thousands of cycles and for years of reliable operation.

HDA 421 - High temperature sensor series

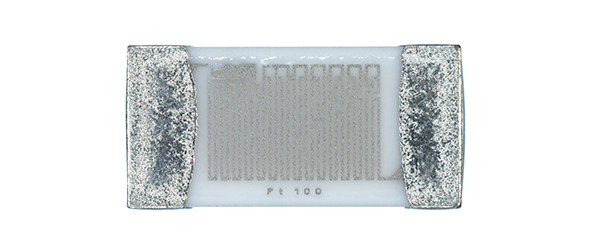

Soot Sensors Monitor Particle Filters

To meet the legal requirements for the built-in diagnostic system (OBD2) for monitoring diesel particulate filters (DPF), OEMs are looking for soot sensors with faster reaction times and higher sensitivity compared to existing solutions. The sensors need to reset and clean itself after a measurement has happened.

YAGEO Nexensos combined it material expert knowledge and experience in thin and tick film Pt technology to provide a soot sensor element for this measuring challenge. Another challenge posed by resistive soot sensors is that they necessarily entail open (unprotected) circuit paths and are therefore exposed to all exhaust-related substances across a wide temperature range from –40 °C to 900 °C. YAGEO Nexensos supports sensor makers for the housing design and can simulate the process and test the sensor on a soot test bench.

Precision and Reliability are not Limited to High Temperature

Its high precision, low drift and wide temperature range makes Pt sensor elements an ideal and reliable solutions to for various other applications:

- Engine oil temperature monitoring

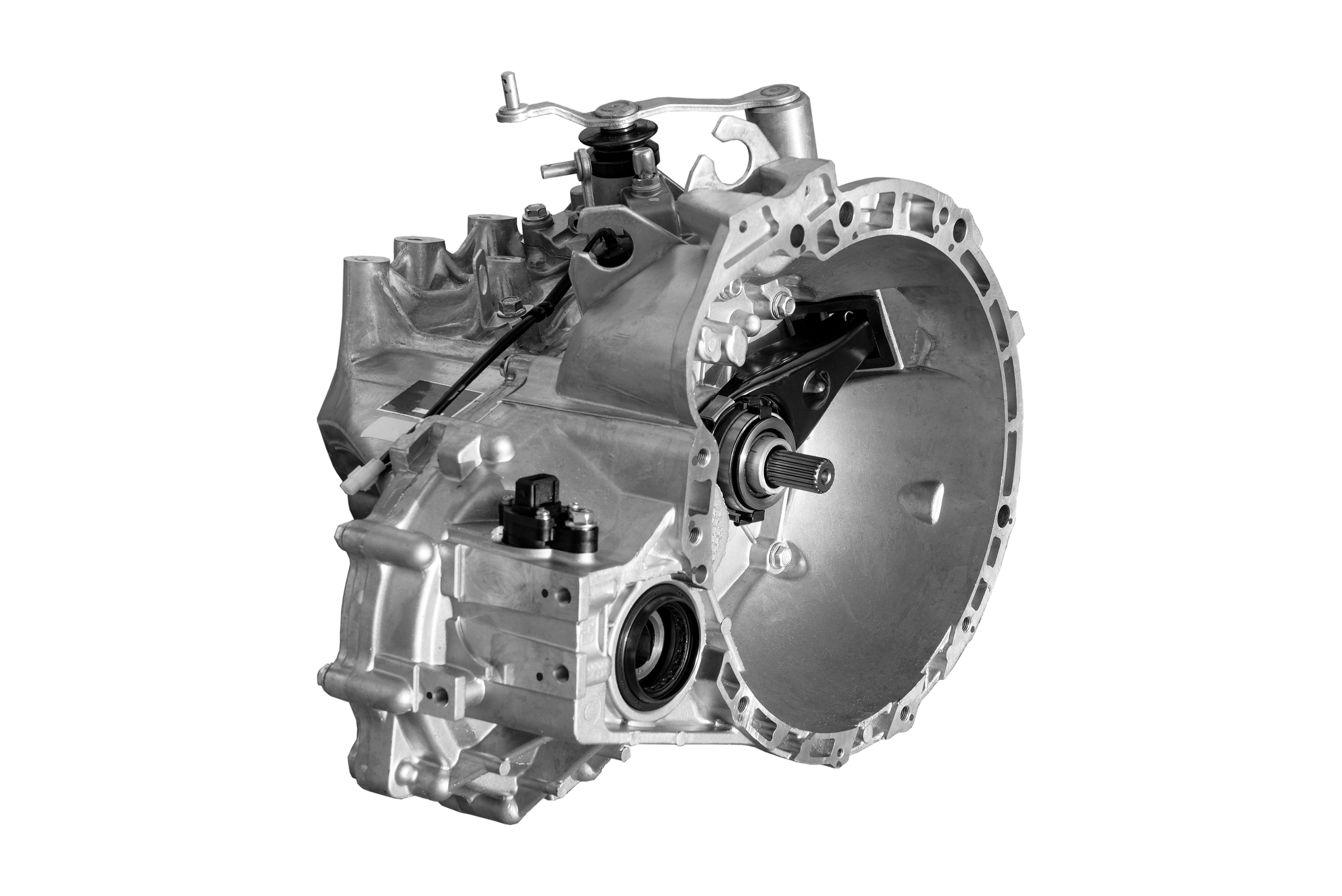

- Transmission oil monitoring and gear box protection

- SCR system control

- Control of heaters

- Component protection

- Indoor climate control

YAGEO Nexensos - The Expert for Maximum Reliability in Temperature Sensing

YAGEO Nexensos combines exclusive expertise from thin-film platinum technology and circuit technology with the utmost manufacturing precision. Because of this unique combination, we are your first choice for the development of reliable and innovative solutions. We work with you to find the best solution for your needs, and we support you from the idea to design to technical support in series production.

Features

- Precise measurement data over a very wide temperature range (to >1000 °C)

- High long-term stability

- Proven, high reliability

- Available in large quantities

- Application-oriented designs